More About AIGE

Milestones:

1) Creation of training data through the simulations of packings

2) Generation of a representation of a vector field

3) Reconstruction of the particles from the 3D representation using a CNN

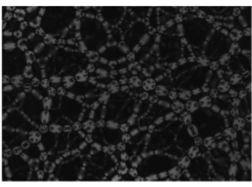

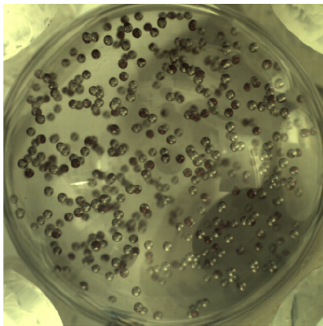

The use of the stress optics method for the investigation of granular packings has led to a variety of findings in recent years, especially for systems in two dimensions, for example with regard to the critical behavior at the so-called jamming transition (Majmudar et al., 2007). Both in the laboratory and in experiments in microgravity, these experiments are extended to three dimensions by Yu et al. (2014); and Fischer et al. (2021). In the ESA experiment VipGran/SpaceGrains, the aforementioned transitions as well as sound and shear are to be investigated in three dimensions, for which stress optics promises otherwise impossible insights into the physical mechanisms.

The project applied for here is intended to support the development of the experiment and its evaluation. The aim of the project is to determine the contact forces within a three-dimensional granulate packing with the aid of stress optics. To achieve the project goal, the necessary data evaluation is broken down into several subtasks. We want to show that each of these subtasks can be solved efficiently and accurately using machine learning methods. First, different packings consisting of soft spheres are realized by computer simulations, cf. Petit (2020). The next step of data evaluation consists of generating a continuous, three-dimensional representation of a vector field (the angle-dependent rotation of the polarization axis), which was described for the first time in 2020 (Mildenhall et al., 2020). The second step reconstructs the contact forces acting on each particle separately from the 3D representation of the polarization angle rotation. For this we will use 3D Convolutional Neural Networks (CNN). A two-dimensional proof of concept for this step was provided by Sergazinov & Kramar (2021) at the end of 2020.

Looking ahead, it can certainly be expected that increased computing capacity will be available for experiments on the ISS in the future. This means that fast data analysis, such as that developed above, can also be used for control directly on the ISS or in the user center. The determination of critical points can then be fully or partially automated and the accuracy of the data in relation to physical transitions should achieve unprecedented precision in the parameters.

Our Work

Solving the 3D stress-birefringence problem in granular solids with a deep neural network

Granular Solids: Microscopic interactions to Macroscopic phenomenon

Stress-optic observation to complete stress maps

Stress-optic observation to complete stress maps

- Local stress dependent phase shift

- Fringe patterns indicating stress distributions

- Detection of force chains in ensemble

AI to reconstruct the stress map

- From stress-optic experiments of granular assemblies

- Start with the light intensity information

- Generate stress-map within 3D granular medium

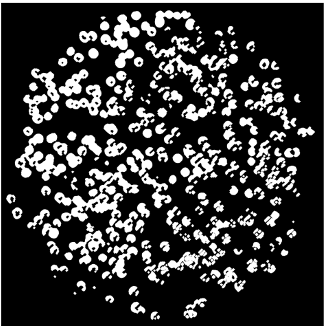

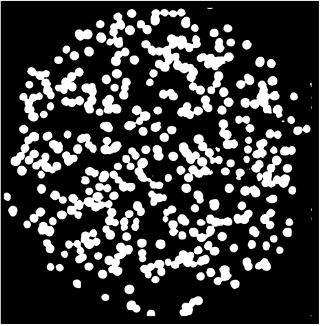

Learning of highly resolved particle positions by Neural-network

- Aim: Track particle trajectories in experiments with dilute granular systems in low-gravity environment

- Method: A convolutional neural network (CNN) with U-Net architecture is trained for image segmentation

- Achievement: Particles are tracked from images taken from orthogonal coordinate directions, with higher accuracy and greater ease

- Future: Focus on combining and calibrating current tracking data to achieve efficient particle tracking in 3D

Our Team

Prof. Dr. Matthias Sperl

Dr. Peidong Yu

Dr. Saswati Ganguly

Dr. Matthias Schröeter

Mr. Fahad Puthalath

Mr. Dorian Didier Feisel

Publications

Journals:

[28] M. Klein, N. Dormagen, C. Dietz, M. Thoma, M. Schwarz: Enhancing Particle String Detection in Electrorheological Plasmas Using Asymmetrical Kernel Convolutional Networks, Machine Learning: Science and Technology, 2024

[27] M. Lahr, J. Loh, M. Schwarz, M. Lemme, T. Gemmeke: Vehicle Surroundings Perception Using Micro-electromechanical Systems Inertial Sensors, Advanced Intelligent Systems, Wiley, 2024

Conference Paper:

[89] M. Schwarz, N. Dormagen, M. Klein, S. Pappert, A. S. Schmitz, M. Thoma, AI Algorithms for Plasma Particle Tracking, MIXDES, Gdansk, Poland, 2024

Patents:

[71] M. Schwarz, P. Gieschke, V. Kramer-Sinziger: US11952263B2 – Micromechanical sensor device and corresponding manufacturing method, Robert Bosch GmbH, 2024

Send Us A Message

Whether you are curious about the our work or want to collaborate with us, reach out to us. We are listening.