More About AIPEX

Milestones:

1) Data compression of image data with test data from PK4

2) Image data processing using AI with test data from PK4

3) Application of AI to experiment with e.g. FPGA with test data from PK4

The primary goal is to develop an AI method kit in the form of a framework and best practices for applications in the field of experiment evaluation in space. Aspects of data processing, e.g. optimal compression of image data, aspects of the interfaces to potential AI and also aspects of the optimal AI algorithm play an essential role here. AI algorithms should not only have an application, but should also be explainable. This means, among other things, the use of explainable AI and understanding why the AI made the decision it did are essential for future experiments and the associated use of AI. Furthermore, insights are also to be gained regarding the algorithms associated with different experiment classes themselves, i.e. when is it appropriate to use a supervised or unsupervised learning algo.

Potential use case Dusty plasmas under weightlessness: Complex plasmas are studied under weightlessness on the ISS and on parabolic flights. The PK-4 experiment has been on the ISS since 2014. Its successor, the COMPACT user facility, is planned for use on the ISS.

In addition to the flight model, there is a ground model for PK-4 at CADMOS in Toulouse and two Science Reference Models (SRMs). The SRMs are used to coordinate the ISS experiments, in particular to test proposed experiments, to develop experiment protocols and software and to troubleshoot problems on the ISS. The SRM is largely identical to the flight model on the ISS in terms of function and programming. Parabolic flight experiments, partly proposed by international partners of the PK-4 Science Team, were undertaken to test and complement ISS experiments. Experiments proposed, developed and tested by the JLU Science Team will be carried out in consultation and close contact with the Joint Institute for High Temperatures (JIHT) in Moscow. AI has already been used in PK-4 for experiment evaluation in the form of machine learning.

A major challenge with PK-4 on the ISS is the large amount of data per experiment campaign (several 100 GB) and the need for astronauts to carry out the experiments. This project aims to investigate the use of AI for data reduction through image analysis on the ISS in real time and for possible automated experiment control. To this end, corresponding tests are to be carried out with PK-4 in parabolic flights under zero-gravity conditions.

The University of Greifswald has been carrying out parabolic flights for years, including for the development of stereoscopic camera diagnostics, which are to be used in COMPACT. Due to the complexity of the stereoscopic data, the use of AI methods is particularly suitable here.

Investigations into the use of AI for experiment control and data processing for future projects on complex plasmas in zero gravity represent a potential use case for AIMS (Artificial Intelligence Meets Space). The Department of Electrical Engineering and Information Technology at the Technische Hochschule Mittelhessen (THM) in Giessen will play a leading role in this, and will also be involved in the experiment control of PK-4.

THM and JLU have been working closely together for several years in the field of electric space propulsion. The University of Greifswald is in the process of using machine learning methods for some aspects of experiment evaluation. In cooperation with THM, these activities are now to be expanded and optimized in this project.

Our Work

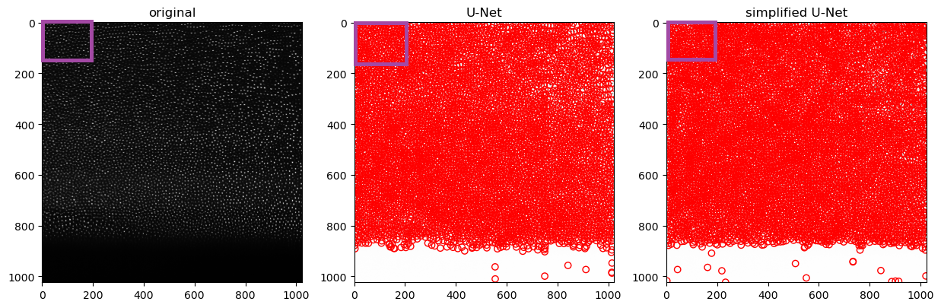

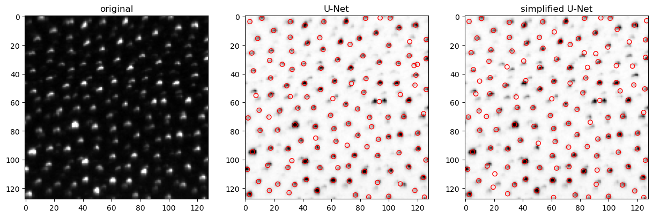

Particle Detection using U-Net

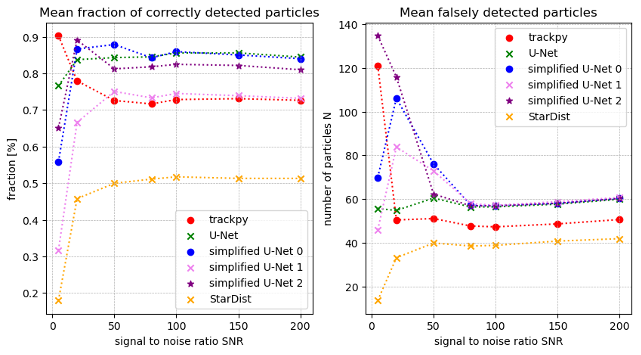

Detecting micron-sized particles is an essential task for the analysis of complex plasmas because a large part of the analysis is based on the initially detected positions of the particles. Accordingly, high accuracy in particle detection is desirable. Previous studies have shown that machine learning algorithms have made great progress and outperformed classical approaches. Our work presents an approach for tracking micron-sized particles in a dense cloud of particles in a dusty plasma at Plasmakristall-Experiment 4 using a U-Net. The U-net is a convolutional network architecture for the fast and precise segmentation of images that was developed at the Computer Science Department of the University of Freiburg. The U-Net architecture, with its intricate design and skip connections, has been a powerhouse in achieving precise object delineation. However, as experiments are to be conducted in resource-constrained environments, such as parabolic flights, preferably with real-time applications, there is growing interest in exploring less complex U-net architectures that balance efficiency and effectiveness. We compare the full-size neural network, three optimized neural networks, the well-known StarDist and trackpy, in terms of accuracy in artificial data analysis. Finally, we determine which of the compact U-net architectures provides the best balance between efficiency and effectiveness. We also apply the full-size neural network and the the most effective compact network to the data of the PK-4 experiment. The experimental data were generated under laboratory conditions.

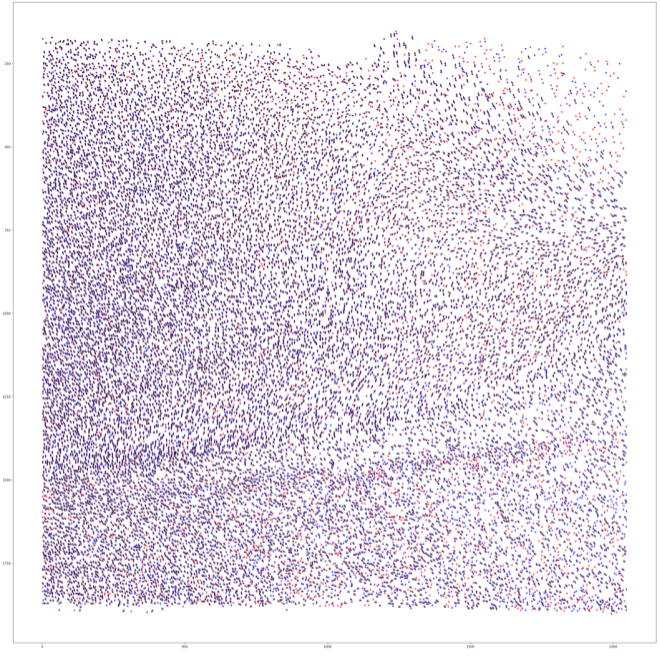

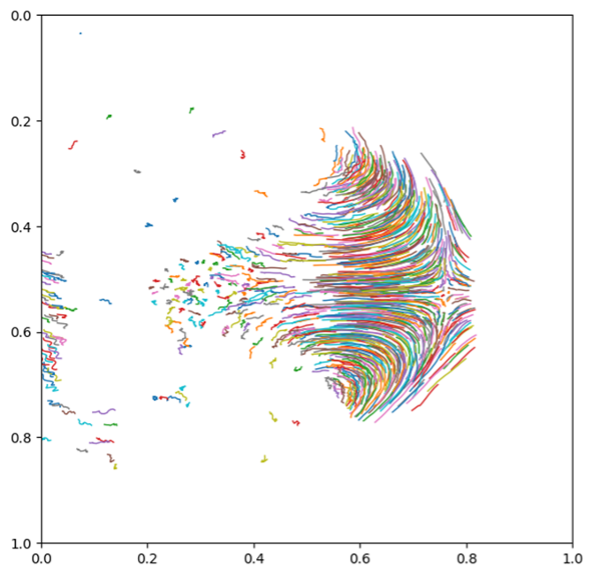

Self-Organizing Map for Particle Tracking Velocimetry

Analyzing particle flows in complex plasmas requires a reliable algorithm for the matching of particles between recorded images. This particle tracking velocimetry (PTV) is not always a trivial task. Especially in situations where no knowledge of the underlying flow field is given and complex flows are present, many algorithms encounter problems in accurately determining particle matches and recognizing traces. Other methods, such as particle image velocimetry (PIV), create a flow field comparing similar image details to give an overview of the underlying flow. This process ignores the individual movement of particles, which makes it hard to calculate particle bound values, such as angular velocity. Our work presents the implementation of a machine learning based algorithm for particle matching and its application to thermal creeps in complex plasmas. Additionally, we develop solutions to accelerate the matching process to enable fast particle trace analysis.

Figure Below: Particle matching results for 50 consecutive images displaying only particles tracked over at least 15 images.

String Formation Detection

Under different plasma conditions and electric fields in a complex plasmathe plasma particles organize themselves in a string-like or chain-like manner. A phasetransition from string-like to an isotropic particle distribution is observed at differentelectrical conditions. The streaming of charged ions around plasma particles withthe surrounding electric field gives the plasma its electrorheological properties. The visibility of individual particles in a complex plasma opens up the opportunity toexamine properties and phase transitions of such electrorheological fluids in detail.Because of the limited one-dimensional symmetry, determining the configuration of aparticle andrecognizing strings in particle distributions is not always straightforward.Several approaches have already been used to analyze particle clouds while eitherconsidering each particle locally orconsidering the particle cloud as a whole withoutproviding information about single particle configurations. Our work presents a newmachine learning approach that takes advantage of particle distributions over the entireparticle cloud and detects all string-like particles at once, using a convolutional neuralnetwork in form of an encoder-decoder network with asymmetric kernel convolutions.This not only enhances the result quality but also accelerates the evaluation process,possibly enabling real-time analyses on electrorheological phase transitions, whileachieving an accuracy of over 95 % on real manually labelled data.

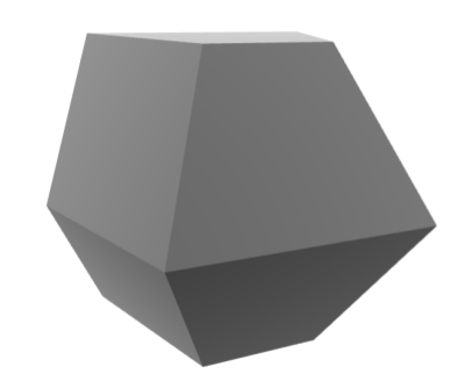

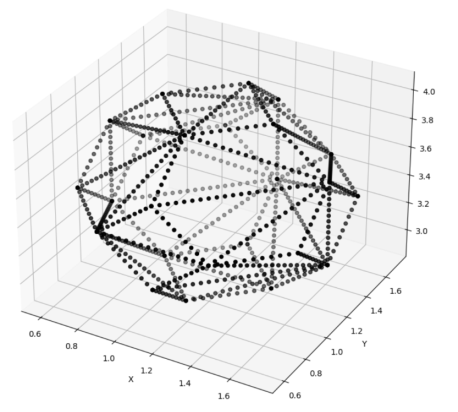

Detecting Ordered Structures

Due to strong interactions between the microparticles, ordered structures called plasma crystals can emerge. Identifying those ordered structures is a common task in physics. Various analysis methods have been developed to retrieve reliable information about crystals. Some of the most popular methods implement an order parameter derived from the location of neighboring particles, while other methods identify topological symmetries of the neighborhood of a particle. These methods all have in common that they try to find certain symmetries to identify crystalline structures. This work is dedicated to developing an alternative analysis algorithm that aims to distinguish between the structures fcc, bcc, and hcp. We aim to classify ordered structures directly based on their three-dimensional arrangement, without the need to determine local parameters. To achieve this, we determine the three-dimensional Voronoi cells of a point cloud, which we use to reconstruct their structure in point clouds. These point clouds are then classified using the well-known PointNet. The model is trained using labeled data, and the PointNet architecture proves to be particularly robust under high noise conditions.

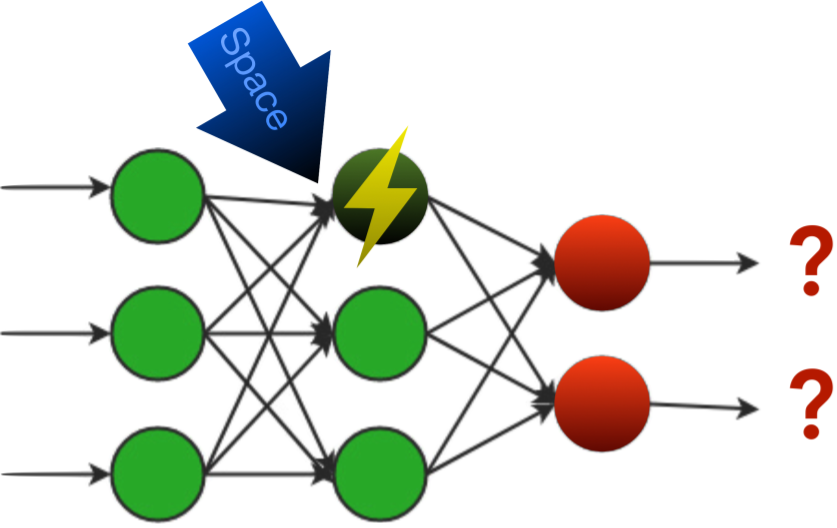

AIPEX & Cosmic Radiation

Estimate influence of radiation in orbit on AI for PK-4

The developed network architecture designed by Niklas Dormagen and hardware selected by Max Klein already perform very well on earth, but the environment in space is slightly different, so we need to ensure the quality of the analysis is consistent and there is no loss in performance over time onboard the ISS.

To do so, we estimate which space conditions can have an impact on the memory of our devices and thus on the weights of the neural network stored in the memory. We found out that cosmic radiation will be the biggest influence. So we set up a simulation of changed weights to study their impact on the overall performance and to identify corner cases. Currently we are also designing experiments to analyze the AI under the extreme of conditions that could occur in space.

Finally, it is our goal to minimize the influence on the performance of the AI and to invent methods to prevent or repair irradiation damage.

Our Team

Prof. Mike Schwarz

Niklas Dormagen

Max Klein

Sarah Pappert

Publications

Journals

[26] N. Dormagen, M. Klein, M. Thoma, M. Schwarz: Multi Particle Tracking in complex plasmas using a simplified and compact U-Net, Journal of Imaging, MDPI, 2024

[25] C. Römer, N. Dersch, G. Darbandy, M. Schwarz, Y. Han, Q.-T. Zhao, A. Kloes: Physics-Based Compact Current Model for Schottky Barrier Transistors at Deep Cryogenic Temperatures Including Band Tail Effects and Quantum Oscillations, Solid-State Electronics 212, 108846, 2024

[24] N. Dersch, E. Perez-Bosch Quesada, E. Perez, C. Wenger, C. Roemer, M. Schwarz, A. Kloes: Efficient circuit simulation of a memristive crossbar array with synaptic weight variability, Solid-State Electronics 209, 108760, 2023

[23] C. Römer, N. Dersch, G. Darbandy, M. Schwarz, Y. Han, Q.-T. Zhao, A. Kloes: Compact modeling of Schottky barrier field-effect transistors at deep cryogenic temperatures, Solid-State Electronics, 2023

[22] M. Schwarz, T. D. Vethaak, V. Derycke, A. Francheteau, B. Iniguez, S. Kataria, A. Kloes, F. Lefloch, M. C. Lemme, J. P. Snyder, W. M. Weber and L. E. Calvet: The Schottky barrier transistor in emerging electronic devices, Nanotechnology, 2023

[21] C. Römer, G. Darbandy, M. Schwarz, J. Trommer, A. Heinzig, T. Mikolajick, W.M. Weber, B. Iniguez, A. Kloes: Physics-Based DC Compact Modeling of Schottky Barrier and Reconfigurable Field-Effect Transistors, IEEE Journal of the Electron Devices Society 10, 2021

[20] M. Schwarz, A. Kloes, D. Flandre: Temperature-Dependent Performance of Schottky-Barrier FET Ultra-Low-Power Diode, Solid-State Electronics, Vol. 184, No. 1, 2021

[19] S. A. Ahsan, S. Kumar Singh, C. Yadav, E. G. Marin, A. Kloes, and M. Schwarz: A Comprehensive Physics-based Current-Voltage SPICE Compact Model for 2D-Material-based Top-contact Bottom-gated Schottky-Barrier FETs, IEEE Transactions on Electron Devices, Vol. 99, No. 1, 2020

[18] A. Farokhnejad, M. Schwarz, M. Graef, F. Horst, B. Iñíguez, F. Lime, A. Kloes: Analytical Modeling of Capacitances in Tunnel-FETs Including the Effect of Schottky Barrier Contacts, Solid-State Electronics, 2019

[17] M. Schwarz, L. E. Calvet, J. P. Snyder, T. Kraus, U. Schwalke, A. Kloes: Analysis and Investigation of Schottky Barrier MOSFET Current Injection with Process and Device Simulation, International Journal of Microelectronics and Computer Science (IJMCS), Vol. 9, No. 1, 2018

[16] M. Schwarz, L. E. Calvet, J. P. Snyder, T. Kraus, U. Schwalke, A. Kloes: Simulation Framework and Thorough Analysis of the Impact of Barrier Lowering on the Current in SB-MOSFETs, International Journal of Microelectronics and Computer Science (IJMCS), Vol. 8, No. 2, 2017

[15] M. Schwarz, L. E. Calvet, J. P. Snyder, T. Kraus, U. Schwalke, A. Kloes: On the Physical Behavior of Cryogenic IV and III-V Schottky Barrier MOSFET Devices, IEEE Transactions on Electron Devices, Vol. 64, No. 9, 2017

[14] M. Schwarz, A. Kloes: Analysis and Performance Study of III-V Schottky Barrier Double-Gate MOSFETs Using a 2-D Analytical Model, IEEE Transactions on Electron Devices, Vol. 63, No. 7, 2016

[13] M. Schwarz, A. Kloes: 2D physics-based closed-form modeling of dopant segregated Schottky barrier UTB MOSFETs, Solid-State Electronics, Vol. 99, No. 1, 2014

[12] A. Kloes, M. Schwarz, T. Holtij, A. Navas: Quantum Confinement and Volume Inversion in MOS3 Model for Short-Channel Tri-Gate MOSFETs, IEEE Transactions on Electron Devices, Vol. 60, No. 8, 2013

[11] M. Schwarz, T. Holtij, A. Kloes, B. Iñíguez: Compact Modeling Solutions for SOI Short-Channel Schottky Barrier MOSFETs, Solid-State Electronics, Vol. 82, No. 1, 2013

[10] M. Schwarz, T. Holtij, A. Kloes, B. Iñíguez: Performance Study of a Schottky Barrier Double-Gate MOSFET Using a 2D Analytical Model, IEEE Transactions on Electron Devices, Vol. 60, No. 2, 2013

[9] T. Holtij, M. Schwarz, A. Kloes, B. Iñíguez: Threshold Voltage, and 2D Potential Modeling Within Short-Channel Junctionless DG MOSFETs in Subthreshold Region, Solid-State Electronics, 2013

[8] T. Holtij, M. Schwarz, A. Kloes, B. Iñíguez: 2D Analytical Calculation of the Parasitic Source/Drain Resistances in DG-MOSFETs Using the Conformal Mapping Technique, IETE Journal of Research, Vol. 38, No. 3, 2012

[7] M. Schwarz, T. Holtij, A. Kloes, B. Iñíguez: Complex 2D Electric Field Solution in Undoped Double-gate MOSFETs, IETE Journal of Research, Vol. 38, No. 3, 2012

[6] A. Kloes, M. Schwarz, T. Holtij: MOS3: A New Physics-Based Explicit Compact Model for Lightly-Doped Short-Channel Triple-Gate SOI MOSFETs, IEEE Transactions on Electron Devices, Vol. 59, No. 2, 2012

[5] M. Schwarz, T. Holtij, A. Kloes, B. Iñíguez: Analytical Compact Modeling Framework for the 2D Electrostatics in Lightly Doped Double-Gate MOSFETs, Solid-State Electronics, Vol. 69, No. 1, 2012

[4] M. Schwarz, T. Holtij, A. Kloes, B. Iñíguez, 2D Analytical Calculation of the Electric Field in Lightly Doped Schottky Barrier Double-Gate MOSFETs and Estimation of the Tunneling/Thermionic Current, Solid-State Electronics, Vol. 63, No. 1, 2011

[3] A. Kloes, M. Weidemann, M. Schwarz: Analytical Current Equation for Short-Channel SOI Multigate FETs Including 3D Effects, Solid-State Electronics, Vol. 54, No. 11, 2010

[2] M. Schwarz, M. Weidemann, A. Kloes, B. Iñíguez: 2D Analytical Calculation of the Electrostatic Potential in Lightly Doped Schottky Barrier Double-Gate MOSFET, Solid-State Electronics, Vol. 54, No. 11, 2010

[1] M. Weidemann, A. Kloes, M. Schwarz, B. Iñíguez: Two-dimensional analytical model for channel length modulation in lightly-doped DG FETs, Electronics and Telecommunications Quarterly published by Committee of Electronics and Telecommunication of the Polish Academy of Sciences, Vol. 55, No. 4, 2009

Conferences

[88] M. Klein, N. Dormagen, A. S. Schmitz, M. Thoma, M. Schwarz, Particle Matching, Tracing and Velocimetry with Self-Organizing Map in Complex Plasmas, International Conference on Machine Learning and Applications 2023, Jacksonville, USA, 2023

[87] A. Kloes, Y. Han, Q.-T. Zhao, C. Roemer, M. Schwarz, Evaluation of approaches for analytical calculation of tunneling currents in Schottky barrier transistors, 7th Symposium on Schottky Barrier MOS Devices, Paris, France, 2023

[86] C. Roemer, N. Dersch, G. Darbandy, M. Schwarz, Y. Han, Q.-T. Zhao, B. Iñíguez, A. Kloes: DC Compact Modeling of Schottky Barrier Field-Effect Transistors at Deep Cryogenic Temperatures, 7th Symposium on Schottky Barrier MOS Devices, Paris, France, 2023

[85] M. Schwarz, G. Darbandy, C. Roemer, N. Dersch, A. Kloes , Simulation and Modeling of Silicon Semiconductor Devices and Sensors, MIXDES, Krakow, Poland, 2023

[84] A. Kloes, Y. Han, Q.-T. Zhao, C. Roemer, M. Schwarz, Comparison Between WKB and Wavelet Approach for Analytical Calculation of Tunneling Currents in Schottky Barrier Field-Effect Transistors, MIXDES, Krakow, Poland, 2023

[83] N. Dormagen, M. Klein, M.H. Thoma, M. Schwarz, Machine Learning Approach for Multi Particle Tracking in Complex Plasmas, MIXDES, Krakow, Poland, 2023

[82] A. Kloes, A. Nikolaou, N. Dersch, C. Roemer, G. Darbandy, M. Schwarz, Noise-Based Simulation Approach For Statistical Analysis of Parameter Fluctuations in Circuits, MIXDES, Krakow, Poland, 2023

[81] M. Schwarz: Introduction into Artificial Intelligence, Presentation at College “Adolf-Reichwein-Schule”, Germany, 2023

[80] N. Dersch, E. Perez-Bosch Quesada, E. Perez, C. Wenger, C. Roemer, M. Schwarz, A. Kloes: Efficient Circuit Simulation of a Memristive Crossbar Array with Synaptic Weight Variability, ULIS/EuroSOI, Tarragona, Spain, 2023

[79] C. Roemer, N. Dersch, G. Darbandy, M. Schwarz, Y. Han, Q.-T. Zhao, B. Iñíguez, A. Kloes: Compact Modeling of Schottky Barrier Field-Effect Transistors at Deep Cryogenic Temperatures, ULIS/EuroSOI, Tarragona, Spain, 2023

[78] C. Roemer, G. Darbandy, M. Schwarz, J. Trommer, A. Heinzig, T. Mikolajick, W. Weber, B. Iñíguez, A. Kloes: Compact Modelling of Injection Current and Channel-Resistance Effects in

Reconfigurable Field-Effect Transistors, 6th Symposium on Schottky Barrier MOS Devices, Gießen, Germany, 2022

[77] C. Römer, G. Darbandy, M. Schwarz, J. Trommer, M. Simon, A. Heinzig, T. Mikolajick, W. Weber, B. Iñíguez, A. Kloes, Compact Modeling of Channel-Resistance Effects in Reconfigurable Field-Effect Transistors, MIXDES, Wroclaw, Poland, 2022

[76] N. Bogun, E. Perez-Bosch Quesada, E. Perez, C. Wenger, A. Kloes, M. Schwarz, Analytical Calculation of Inference in Memristor-based Stochastic Artificial Neural Networks, MIXDES, Wroclaw, Poland, 2022

[75] L. Calvet, O. Rennard, J. Snyder, M. Schwarz: Schottky barrier and organic devices for neuromorphic circuits, The Future of Nanoelectronic Devices and Systems Beyond Moore Workshop, SiNANO Institute, Caen (Virtual), France, 2021

[74] C. Roemer, G. Darbandy, M. Schwarz, B. Iñíguez, A. Kloes: Closed-Form Field Emission Current Model for Schottky Barrier Field-Effect Transistors, Graduated Students Meeting URV, Tarragona (Virtual), Spain, 2021

[73] L. Calvet, J. Snyder, M. Schwarz: The Schottky barrier transistor in all its forms, 5th Symposium on Schottky Barrier MOS Devices, Tarragona (Virtual), Spain, 2021

[72] C. Roemer, G. Darbandy, M. Schwarz, J. Trommer, A. Heinzig, T. Mikolajick, W. Weber, B. Iñíguez, A. Kloes: Compact Modelling of Dually-Gated Reconfigurable Field-Effect Transistors, 5th Symposium on Schottky Barrier MOS Devices, Tarragona (Virtual), Spain, 2021

[71] M. Schwarz, A. Buhmann: Safety Application Car Crash Detection Using Multiclass Support Vector Machine, MIXDES, Wroclaw (Virtual), Poland, 2021

[70] M. Schwarz: Simulation and Modeling Methodologies: Enabler for Neuromorphic Computing Applications, MIXDES, Wroclaw (Virtual), Poland, 2021

[69] C. Roemer, G. Darbandy, M. Schwarz, J. Trommer, A. Heinzig, T. Mikolajick, W. M. Weber, B. Iniguez, and A. Kloes, “Uniform DC Compact Model for Schottky Barrier and Reconfigurable Field-Effect Transistors,” Third Latin American Electron Devices Conference (LAEDC), Virtual, 2021

[68] Laurie Calvet, Paoline Coulson, John Snyder, Benjamin Iniguez, Mike Schwarz: Schottky barrier devices for neuromorphic computing, 2020 Joint Spring MOS-AK Workshop&IEEE EDS MQ „Non-Conventional Devices and Technologies“ & Symposium on Schottky Barrier MOS Devices, Gießen (Virtual), Germany, 2020

[67] M. Schwarz: Simulation and Modeling of Semiconductor Devices in MEMS, 2020 Joint Spring MOS-AK Workshop&IEEE EDS MQ „Non-Conventional Devices and Technologies“ & Symposium on Schottky Barrier MOS Devices, Gießen (Virtual), Germany, 2020

[66] M. Schwarz, A. Kloes, D. Flandre: Schottky-Barrier FET Ultra-Low-Power Diode, ULIS/EuroSOI, Caen (Virtual), France, 2020

[65] M. Schwarz: Sensor Design – From Prototype to Series DL, IEEE Poland MQ, Wroclaw (Virtual), Poland, 2020

[64] M. Schwarz: Sensor Design made by Bosch (Invited), MIXDES, Wroclaw (Virtual), Poland, 2020

[63] M. Schwarz: Challenges and capabilities of industrialization for high-tech MEMS design and simulation methodologies (Invited), 5th Annual Automotive Sensors and Electronics Summit, Munich, Germany, 2020

[62] L. E. Calvet, M. Schwarz, J. P. Snyder: Advantages of SB-MOS for neuromorphic computing, 3rd Symposium Schottky Barrier MOS Devices, Paris, 2019

[61] M. Schwarz, L. E. Calvet, J. P. Snyder, T. Krauss, U. Schwalke, A. Kloes: SBMOS device modeling with applications to neuromorphic computing, 3rd Symposium Schottky Barrier MOS Devices, Paris, 2019

[60] A. Hald, R. Wolf, J. Seelhorst, J. Scheible, J. Lienig, S. Tibus and M. Schwarz: Parasitic Extraction Methodology for MEMS Sensors with Active Devices, SMACD, Lausanne, Switzerland, 2019

[59] M. Schwarz: The Need of Simulation Methodologies for Active Semiconductor Devices in MEMS (Invited), MIXDES, Rzeszów, Poland, 2019

[58] M. Schwarz: Industrialization of High-Tech MEMS (Invited), Université catholique de Louvain, Louvain-la-Neuve, Belgium, 2019

[57] M. Schwarz, V.Senz, A. Dannenberg, F. Heuck, T. Friedrich, C. Sorger, J. Franz: Simulation Methodologies for Active Semiconductor Devices in MEMS, EuroSimE, Hannover, 2019

[56] L.E. Calvet, C. Bennett, D. Querlioz, T. Krauss, U. Schwalke, A. Kloes, M. Schwarz: Compact Modeling for Neuromorphic Applications, MOS-AK Workshop at ESSDERC, Dresden, 2018

[55] M. Schwarz, L. E. Calvet, J. P. Snyder, T. Krauss, U. Schwalke, A. Kloes: Schottky Barrier MOSFET Device Physics for Cryogenic Applications, MOS-AK Workshop at ESSDERC, Dresden, 2018

[54] M. Schwarz, L. E. Calvet, J. P. Snyder, T. Krauss, U. Schwalke, A. Kloes: Schottky Barrier MOSFET Simulation and Modeling Methodologies, Workshop at NamLab TU Dresden, Dresden, 2018

[53] L.E. Calvet, C. Bennett, D. Querlioz, T. Krauss, U. Schwalke, A. Kloes and M. Schwarz: Modeling of neuromorphic devices, 2nd Symposium Schottky Barrier MOS Devices, Darmstadt, 2018

[52] A. Farokhnejad, M. Schwarz, M. Graef, F. Horst, B. Iñíguez, F. Lime, A. Kloes: Effect of Schottky Barrier Contacts on Measured Capacitances in TFETs,Graduated Student Meeting on Electronic Engineering, Tarragona, Spain, 2018

[51] M. Schwarz, L. E. Calvet, J. P. Snyder, T. Krauss, U. Schwalke, A. Kloes: Wrap-Up of Schottky Barrier Simulation Methodologies, 2nd Symposium Schottky Barrier MOS Devices, Darmstadt, 2018

[50] M. Schwarz, L. E. Calvet, J. P. Snyder, T. Krauss, U. Schwalke, A. Kloes: Process and Device Simulation of Schottky Barrier MOSFETs for Analysis of Current Injection, MIXDES, Gdynia, Poland, 2018

[49] A. Farokhnejad, M. Schwarz, M. Graef, F. Horst, B. Iñíguez, F. Lime, A. Kloes: Effect of Schottky Barrier Contacts on Measured Capacitances in Tunnel-FETs, EuroSOI-ULIS, Granada, Spain, 2018

[48] L. E. Calvet, C. Bennett, R. Merine, D. Querlioz, S. Lenfant, D. Guerin, T. Krauss, M. Schwarz: Silicon Nanowires Dressed with REDOX Molecules for Memristive Devices, SINDREM, 2017

[47] M. Schwarz, J. P. Snyder, T. Krauss, U. Schwalke, L. E. Calvet, A. Kloes: Simulation Framework for Barrier Lowering in Schottky Barrier MOSFETs, MIXDES, Bydgoszcz, Poland, 2017

[46] M. Schwarz, A. Kloes: III-V SB MOSFETs: Analytical Modeling and Performance Analysis From Room to Cryogenic Temperature, MOS-AK Workshop at ESSDERC, Lausanne, 2016

[45] M. Schwarz, A. Kloes: Analysis and 2D Analytical Modeling of III-V Schottky Barrier Double-Gate MOSFETs, MIXDES, Lodz, Poland, 2016

[44] M. Schwarz, J. Franz, M. Reimann: The Future is MEMS – Design Consideration of Microelectromechanical Systems at Bosch (Invited), MIXDES, Torun, Poland, 2015

[43] M. Schwarz: Design of Microelectromechanical Systems at Bosch, Graduation Ceremony TH Mittelhessen Faculty Information- and Communication, Gießen, Germany, 2014

[42] F. Hain, M. Graef, M. Schwarz, T. Holtij, A. Kloes, B. Iñíguez: Analytical Model for the Potential in Bottom Contact OFETs and Approach for Calculation of the Tunneling/Thermionic Source/Drain Injection Current, ICOE, Grenoble, France, 2013

[41] A. Kloes, M. Graef, F. Hain, T. Holtij, M. Schwarz: COMON: SOI Multigate Devices Modeling, Spring MOS-AK/GSA Workshop, Munich, Germany, 2013

[40] F. Hain, M. Graef, M. Schwarz, T. Holtij, A. Kloes, B. Iñíguez: Two-Dimensional Analytical Modeling of non-linear Charge Injection in Bottom-Contact Organic Field-Effect Transistors, LOPE-C, Munich, Germany, 2013

[39] T. Holtij, M. Schwarz, M. Graef, F. Hain, A. Kloes, B. Iñíguez: Model for investigation of Ion/Ioff ratios in short-channel junctionless double gate MOSFETs, ULIS, Warwick, England, 2013

[38] M. Graef, M. Schwarz, T. Holtij, F. Hain, A. Kloes, B. Iñíguez: Two-dimensional Bias Dependent Model for the Screening Length in Double-Gate Tunnel-FETs, ULIS, Warwick, England, 2013

[37] M. Graef, M. Schwarz, T. Holtij, F. Hain, A. Kloes: Two-dimensional Analytical Model for Performance Evaluation of Double-Gate Tunnel-FETs, EUROSOI, Paris, France, 2013

[36] T. Holtij, M. Schwarz, M. Graef, F. Hain, A. Kloes, B. Iñíguez: 2D Current Model for Junctionless DG MOSFETs, EUROSOI, Paris, France, 2013

[35] M. Schwarz, T. Holtij, A. Kloes, B. Iñíguez: Investigation of Scaling Behavior of Schottky Barrier Double-Gate MOSFETs Using a 2D Analytical Model, ESSDERC, Bordeaux, France, 2012

[34] T. Holtij, M. Schwarz, A. Kloes, B. Iñíguez: Analytical 2D Modeling of Junctionless and Junction-Based Short-Channel Multigate MOSFETs, ESSDERC, Bordeaux, France, 2012

[33] M. Schwarz, T. Holtij, A. Kloes, B. Iñíguez: Scaling Behavior Investigation of Schottky Barrier DG-MOSFETs Using a 2D Analytical Model, Graduated Student Meeting on Electronic Engineering, Tarragona, Spain, 2012

[32] T. Holtij, M. Schwarz, A. Kloes, B. Iñíguez: VT Based Current Modeling Within Highly Doped Short-Channel Multigate FETs, Graduated Student Meeting on Electronic Engineering, Tarragona, Spain, 2012

[31] M. Schwarz, T. Holtij, A. Kloes, B. Iñíguez: Two-dimensional Physics-based Modeling of Dopant-segregated Schottky Barrier UTB MOSFETs, MIXDES, Warsaw, Poland, 2012

[30] T. Holtij, M. Schwarz, A. Kloes, B. Iñíguez: 2D Analytical Potential Modeling of Junctionless DG MOSFETs in Subthreshold Region Including Proposal for Calculating the Threshold Voltage, ULIS, Grenoble, 2012

[29] M. Schwarz, T. Holtij, A. Kloes, B. Iñíguez: Explicit model for tunneling and thermionic current in Schottky barrier Double-Gate MOSFETs, ULIS, Grenoble, 2012

[28] T. Holtij, M. Schwarz, A. Kloes, B. Iñíguez: 2D Analytical Modeling of the Potential within Juntionless DG MOSFETs in the Subthreshold Regime, EUROSOI, Montpelier, 2012

[27] M. Schwarz, T. Holtij, A. Kloes, B. Iñíguez: Explicit Model Equations for the Tunneling Current Density in Schottky Barrier Double-Gate MOSFETs, EUROSOI, Montpelier, 2012

[26] M. Schwarz, T. Holtij, A. Kloes, B. Iñíguez: 2D Analytical DC Model for Nanoscale Schottky Barrier DG-MOSFETs, ISDRS, University of Maryland, 2011

[25] A. Kloes, M. Schwarz, T. Holtij: Physics-Based, Closed-Form DC Model for Lightly-Doped Short Channel Triple-Gate MOSFETs Including Three-Dimensional Effects, ISDRS, University of Maryland, 2011

[24] M. Schwarz, T. Holtij, A. Kloes, B. Iñíguez: Macro Model for Drift/Diffusion Effects in Short-Channel Undoped Schottky Barrier DG-MOSFETs, MOSAK Workshop at ESSDERC, Helsinki, 2011

[23] A. Kloes, M. Schwarz, T. Holtij: Compact DC Model for Lightly-Doped Short Channel Triple-Gate MOSFETs, MOS-AK Workshop at ESSDERC, Helsinki, 2011

[22] T. Holtij, M. Schwarz, A. Kloes, B. Iñíguez: 2D Analytical Modeling of the Potential in Doped Multiple-Gate-FETs Including Inversion Charge, ESSDERC, Helsinki, 2011

[21] M. Schwarz, T. Holtij, A. Kloes, B. Iñíguez: I-V Model for Lightly Doped Schottky Barrier DG-MOSFETs Including 2D Effects, ESSDERC, Helsinki, 2011

[20] M. Schwarz, A. Kloes, B. Iñíguez: 2D I-V Model for Lightly Doped SB-DGMOSFETs, Graduated Student Meeting on Electronic Engineering, Tarragona, Spain, 2011

[19] M. Schwarz, T. Holtij, A. Kloes, B. Iñíguez: 2D Analytical Framework for Compact Modeling of the Electrostatics in Undoped DG MOSFETs, MIXDES, Gliwice, Poland, 2011

[18] T. Holtij, M. Schwarz, A. Kloes, B. Iñíguez: 2D Analytical Calculation of the Source/ Drain Access Resistance in DG-MOSFET Structures, ULIS, Cork, Ireland, 2011

[17] M. Schwarz, T. Holtij, A. Kloes, B. Iñíguez: 2D Analysis of Source/Drain Carrier Tunneling in Lightly Doped Schottky Barrier DG-MOSFETs Using a Fully Analytical Model, ULIS, Cork, Ireland, 2011

[16] M. Schwarz, A. Kloes, B. Iñíguez: 2D Analytical Calculation of the Current in Lightly Doped Schottky Barrier Double-Gate MOSFET, EUROSOI, Granada, Spain, 2011

[15] T. Holtij, M. Schwarz, A. Kloes: Analytical two-dimensional model for the parasitic source/drain resistance in DG-MOSFETs, MOS-AK Workshop at ESSDERC, Seville, Spain, 2010

[14] M. Schwarz, A. Kloes, B. Iñíguez: 2D Analytical Calculation of the Tunneling Current in Lightly Doped Schottky Barrier Double-Gate MOSFET, ESSDERC, Seville, Spain, 2010

[13] M. Schwarz, A. Kloes, B. Iñíguez: Closed-Form 2D Analytical Model for the Electric Field in Lightly Doped Schottky Barrier Double-Gate MOSFET, Graduated Student Meeting on Electronic Engineering, Tarragona, Spain, 2010

[12] M. Schwarz, A.Kloes, B. Iñíguez: Analytical 2D Model for the Channel Electric Field in Undoped Schottky Barrier DG-MOSFET, MIXDES, Wroclaw, Poland, 2010

[11] M. Schwarz, A.Kloes, B. Iñíguez: 2D Closed-Form Model for the Source/Drain Orthogonal Electric Field in Lightly Doped Schottky Barrier Double-Gate MOSFET, ULIS, Glasgow, 2010

[10] M. Weidemann, A. Kloes, M. Schwarz, B. Iñíguez: Analysis and Modeling of the Pinch-Off Point in a Lightly Doped Asymmetrically Biased Double Gate MOSFET, ISDRS, University of Maryland, USA, 2009

[9] M. Schwarz, M. Weidemann, A.Kloes, B. Iñíguez: Two-Dimensional Model for the Potential Profile in a Short Channel Schottky Barrier DG-FET, ISDRS, University of Maryland, USA, 2009

[8] A. Kloes, M. Weidemann, M. Schwarz: Closed-form current equation for shortchannel triple-gate FETs, MOS-AK Workshop at ESSDERC, Athens, Greece, 2009

[7] M. Weidemann, A. Kloes, M. Schwarz, B. Iñíguez: 2D physics-based compact model of channel length modulation for asymmetrically biased double-gate MOSFETs, ESSDERC, Athens, Greece, 2009

[6] M. Schwarz, M. Weidemann, A. Kloes, B. Iñíguez: 2D Analytical Solution of Potential in Lightly Doped Schottky Barrier Double-Gate MOSFET, ESSDERC, Athens, Greece, 2009

[5] M. Weidemann, A. Kloes, M. Schwarz, B. Iñíguez: 2D physics-based compact model for channel length modulation in lightly doped DG FETs, MIXDES, Lodz, Poland, 2009

[4] A. Kloes, M. Weidemann, M. Schwarz: Analysis of 3D current flow in undoped FinFETs and approaches for compact modeling, MIXDES, Lodz, Poland, 2009

[3] A. Kloes, M. Weidemann, M. Schwarz, T. Holtij: Design Considerations for Undoped FinFETs Based on a 3D Compact Model for the Potential Barrier, ULIS, Aachen, Germany, 2009

[2] M. Schwarz, M. Weidemann, A. Kloes, B. Iñíguez: 2D Analytical Model of the Potential Distribution in Lightly Doped Schottky Barrier DG-MOSFET, Graduated Student Meeting on Electronic Engineering, Tarragona, Spain, 2009

[1] M. Weidemann, M. Schwarz, A. Kloes, B. Iñíguez: Analytical 2D Modelling of Channel Length Modulation in DG FETs, ESSDERC, Edinburgh, Scotland, 2008

Patents

[70] M. Schwarz, J.Kreutzer: DE102020213786A1 – VerfahrenzumBewerteneines Sensors, sowieentsprechendesSensorsystem und VerfahrenzumBetreiben des Sensorsystems, Robert Bosch GmbH, 2022

[69] M. Schwarz, H. Weber: WO2022084551A1 – VerfahrenzumHerstelleneiner Buried-Layer-Schichtstruktur und entsprechende Buried-Layer-Schichtstruktur, Robert Bosch GmbH, 2022

[68] M. Schwarz, H. Weber: DE102020213385A1 – VerfahrenzumHerstelleneiner Buried-Layer-Schichtstruktur und entsprechende Buried-Layer-Schichtstruktur, Robert Bosch GmbH, 2022

[67] M. Schwarz, G. Pozzato, J. Kreutzer, M. Salvatore Santoro: DE102020212007A1 – System for the optical detection of deposits on a surface and a sensor with a system, Robert Bosch GmbH, 2022

[66] M. Schwarz, J.Kreutzer: DE102020212007A1 – Method for detecting a deposit on a sensor system and sensor system, Robert Bosch GmbH, 2022

[65] M. Schwarz, A. Dannenberg: US20220009769A1 – MEMS SENSOR AS WELL AS METHOD FOR OPERATING A MEMS SENSOR, Robert Bosch GmbH, 2022

[64] M. Schwarz, G. Pozzato, J. Friedl, J. Kreutzer, M. Salvatore Santoro, M.Kittel: DE102020206952B3 – Sensor system for the continuous detection of fluids and / or particles and method for operating the sensor system, Robert Bosch GmbH, 2021

[63] M. Schwarz, A. Dannenberg, F. Heuck, P. Engelhart, V. Kramer-Sinzinger: DE102020211230A1 – MikromechanischesDrucksensorelement und VerfahrenzumHerstelleneinesmikromechanischenDrucksensorelements, Robert Bosch GmbH, 2021

[62] M. Schwarz, S. Tibus, I. Simon, F. Rettig, A. Dannenberg: DE102020200357B4 – Detektionseinrichtung für einenmikromechanischenKombinationssensor, Robert Bosch GmbH, 2021

[61] M. Schwarz, V. Senz, T. Friedrich, F. Heuck: US11486782B2 – Micromechanical device and method for manufacturing a micromechanical device, Robert Bosch GmbH, 2021

[60] M. Schwarz, A. Dannenberg, T. Friedrich: US20210130168A1 – Method for manufacturing a substrate having a region mechanically decoupled from a support, method for manufacturing at least one spring, and a substrate, Robert Bosch GmbH, 2021

[59] M. Schwarz, V. Senz, T. Friedrich, F. Heuck, P. Schmollngruber, J. Tomaschko: US20200399116A1 – Bond structures on mems element and asic element, Robert Bosch GmbH, 2020

[58] M. Schwarz, V. Senz, T. Friedrich, F. Heuck, P. Schmollngruber, J. Tomaschko: EP000003774640A1 – Bond structures on mems element and asic element, Robert Bosch GmbH, 2020

[57] M. Schwarz, T. Friedrich, C. Hermes, A. Finn, P. Schmollngruber, H. Weber, A. Scheurle: DE102019202799A1 – Method for producing a MEMS structure and corresponding MEMS structure, Robert Bosch GmbH, 2020

[56] M. Schwarz, A. Dannenberg: WO2020152090A1 – Mems-Sensor sowieVerfahrenzumBetreibeneines Mems-Sensors, Robert Bosch GmbH, 2020

[55] M. Schwarz, A. Dannenberg: DE102019200917A1 – Mems-Sensor sowieVerfahrenzumBetreibeneines Mems-Sensors, Robert Bosch GmbH, 2020

[54] M. Schwarz, P. Gieschke, V. Kramer-Sinziger: DE102019201768A1 – MikromechanischeSensorvorrichtung und entsprechendes Herstellungsverfahren, Robert Bosch GmbH, 2019

[53] M. Schwarz, A. Dannenberg: TW202043136A – Mems-Sensor sowieVerfahrenzumBetreibeneines Mems-Sensors, Robert Bosch GmbH, 2020

[52] M. Schwarz, A. Dannenberg: WO2020152090A1 – Mems-Sensor sowieVerfahrenzumBetreibeneines Mems-Sensors, Robert Bosch GmbH, 2019

[51] M. Schwarz, V. Senz, T. Friedrich, F. Heuck, P. Schmollngruber, J. Tomaschko: CN111936413A – Bond-Strukturen auf MEMS-Element und ASIC Element, Robert Bosch GmbH, 2019

[50] M. Schwarz, V. Senz, T. Friedrich, F. Heuck, P. Schmollngruber, J. Tomaschko: WO2019192797A1 – Bond-Strukturen auf MEMS-Element und ASIC Element, Robert Bosch GmbH, 2019

[49] M. Schwarz, V. Senz, T. Friedrich, F. Heuck, P. Schmollngruber, J. Tomaschko: DE102018205156A1 – Bond-Strukturen auf MEMS-Element und ASIC Element, Robert Bosch GmbH, 2019

[48] M. Schwarz, V. Senz, G. Cazzaniga: WO2019134839A1 – Sensorvorrichtung und VerfahrenzumHerstelleneinerSensorvorrichtung, Robert Bosch GmbH, 2019

[47] M. Schwarz, V. Senz, G. Cazzaniga: DE102018200064A1 – Sensorvorrichtung und VerfahrenzumHerstelleneinerSensorvorrichtung, Robert Bosch GmbH, 2019

[46] M. Schwarz, A. Dannenberg, S. Jaeger, S. Zimmermann: CN109205546A – The micromechanical sensor, Robert Bosch GmbH, 2019

[45] M. Schwarz, A. Dannenberg, S. Jaeger, S. Zimmermann: DE102017211444A1 – Mikromechanischer Sensor, Robert Bosch GmbH, 2018

[44] M. Schwarz, A. Dannenberg, S. Jaeger, S. Zimmermann: CN109384188A – Sensorvorrichtung

und Herstellungsverfahren für eineSensorvorrichtungmitzumindesteinerchemischenoderelektrochemischenDetektiereinrichtung, Robert Bosch GmbH, 2019

[43] M. Schwarz, A. Dannenberg, S. Jaeger, S. Zimmermann: DE102017213351A1 – Sensorvorrichtung und Herstellungsverfahren für eineSensorvorrichtungmitzumindesteinerchemischenoderelektrochemischenDetektiereinrichtung, Robert Bosch GmbH, 2018

[42] M. Schwarz, V. Senz, T. Friedrich, F. Heuck: US20210131897A1 – Micromechanical device and method for producing a micromechanical device , Robert Bosch GmbH, 2021

[41] M. Schwarz, V. Senz, T. Friedrich, F. Heuck: CN111164401A – Micromechanical device and method for producing a micromechanical device , Robert Bosch GmbH, 2020

[40] M. Schwarz, V. Senz, T. Friedrich, F. Heuck: WO2019020409A1 – MikromechanischeVorrichtung und VerfahrenzurHerstellungeinermikromechanischenVorrichtung, Robert Bosch GmbH, 2018

[39] M. Schwarz, V. Senz, T. Friedrich, F. Heuck: DE102017212875A1 – MikromechanischeVorrichtung und VerfahrenzurHerstellungeinermikromechanischenVorrichtung, Robert Bosch GmbH, 2018

[38] M. Schwarz, A. Dannenberg: DE102017208048B3 – The micromechanical pressure sensor, Robert Bosch GmbH, 2018

[37] M. Schwarz, V. Senz, D. Haug, H.-P. Baer: US10442681B2 – Micromechanical system including a sensitive element and associated manufacturing method, Robert Bosch GmbH, 2019

[36] M. Schwarz, V. Senz, D. Haug, H.-P. Baer: DE102017202605A1 – MikromechanischeAnordnungmiteinemsensitiven Element und dazugehöriges Herstellungsverfahren, Robert Bosch GmbH, 2018

[35] M. Schwarz, A. Dannenberg, T. Friedrich : US20210130168A1 – A method for the mechanical decoupling of the substrate area having the support member from the manufacturing method for manufacturing a spring and at least one kind of the substrate for, Robert Bosch GmbH, 2021

[34] M. Schwarz, A. Dannenberg, T. Friedrich : CN110177757A – A method for the mechanical decoupling of the substrate area having the support member from the manufacturing method for manufacturing a spring and at least one kind of the substrate for, Robert Bosch GmbH, 2019

[33] M. Schwarz, A. Dannenberg, T. Friedrich : TW201834959A – A method for the mechanical decoupling of the substrate area having the support member from the manufacturing method for manufacturing a spring and at least one kind of the substrate for, Robert Bosch GmbH, 2018

[32] M. Schwarz, A. Dannenberg, T. Friedrich : WO2018130374A1 – VerfahrenzumHerstelleneines Substrates miteinem von einem Träger mechanischentkoppeltenBereich, VerfahrenzumHerstellen von mindestenseiner Feder und eines Substrates, Robert Bosch GmbH, 2018

[31] M. Schwarz, A. Dannenberg, T. Friedrich : DE102017200587A1 – VerfahrenzumHerstelleneines Substrates miteinem von einem Träger mechanischentkoppeltenBereich, VerfahrenzumHerstellen von mindestenseiner Feder und eines Substrates, Robert Bosch GmbH, 2018

[30] M. Schwarz, A. Dannenberg, A. Duell, S. Zehringer, S. Oppl, H. Grutzeck, S. Zimmermann,

J. Franz: US20200088598A1 – Linearized micromechanical sensor, Robert Bosch GmbH, 2020

[29] M. Schwarz, A. Dannenberg, A. Duell, S. Zehringer, S. Oppl, H. Grutzeck, S. Zimmermann,

J. Franz: EP3566037B1 – Linearized micromechanical sensor, Robert Bosch GmbH, 2019

[28] M. Schwarz, A. Dannenberg, A. Duell, S. Zehringer, S. Oppl, H. Grutzeck, S. Zimmermann, J. Franz: TW201827329A – Linearized micromechanical sensor, Robert Bosch GmbH, 2018

[27] M. Schwarz, A. Dannenberg, A. Duell, S. Zehringer, S. Oppl, H. Grutzeck, S. Zimmermann,

J. Franz: WO2018127352A1 – Linearized micromechanical sensor, Robert Bosch GmbH, 2018

[26] M. Schwarz, A. Dannenberg, A. Duell, S. Zehringer, S. Oppl, H. Grutzeck, S. Zimmermann, J. Franz: DE102017200057A1 – Linearized micromechanical sensor, Robert Bosch GmbH, 2018

[25] M. Schwarz, T. Lindemann, J. Fritz: TW201813110A – MikromechanischerDrucksensor, Robert Bosch GmbH, 2018

[24] M. Schwarz, T. Lindemann, J. Fritz: WO2018046535A1 – MikromechanischerDrucksensor, Robert Bosch GmbH, 2018

[23] M. Schwarz, T. Lindemann, J. Fritz: DE102016217132A1 – MikromechanischerDrucksensor, Robert Bosch GmbH, 2018

[22] M. Schwarz, S. Jaeger, R. Ehrenpfordt, A. Dannenberg, F. Ante, S. Zehringer, S. Zimmermann, J. Franz, J. Kenntner: DE102016217384A1 – VerfahrenzumHerstelleneinesmikroelektronischenBauteils und entsprechendesmikroelektronischesBauteil , Robert Bosch GmbH, 2018

[21] T. Lindemann, H. Stahl, M. Mitschke, D. Haug, D. Kaercher, A. Dannenberg, M. Schwarz: US10775253B2 – Method for producing a micromechanical component with a exposed pressure sensing device and a micromechanical component, Robert Bosch GmbH, 2021

[20] T. Lindemann, H. Stahl, M. Mitschke, D. Haug, D. Kaercher, A. Dannenberg, M. Schwarz: CN109689566A – VerfahrenzumHerstelleneinesmikromechanischenBauteilsmiteinerfreigestelltenDrucksensoreinrichtung und mikromechanischesBauteil, Robert Bosch GmbH, 2019

[19] T. Lindemann, H. Stahl, M. Mitschke, D. Haug, D. Kaercher, A. Dannenberg, M. Schwarz: KR20190044096A – VerfahrenzumHerstelleneinesmikromechanischenBauteilsmiteinerfreigestelltenDrucksensoreinrichtung und mikromechanischesBauteil, Robert Bosch GmbH, 2019

[18] T. Lindemann, H. Stahl, M. Mitschke, D. Haug, D. Kaercher, A. Dannenberg, M. Schwarz: TW201811660A – Method for producing a micromechanical component with a exempted pressure sensing device and a micromechanical component, Robert Bosch GmbH, 2018

[17] T. Lindemann, H. Stahl, M. Mitschke, D. Haug, D. Kaercher, A. Dannenberg, M. Schwarz: WO2018046307A1 – Method for producing a micromechanical component with a exempted pressure sensing device and a micromechanical component, Robert Bosch GmbH, 2018

[16] T. Lindemann, H. Stahl, M. Mitschke, D. Haug, D. Kaercher, A. Dannenberg, M. Schwarz: DE102016216870B4 – VerfahrenzumHerstelleneinesmikromechanischenBauteilsmiteinerfreigestelltenDrucksensoreinrichtung und mikromechanischesBauteil, Robert Bosch GmbH, 2018

[15] M. Schwarz, I. Herrmann, V. Senz, D. Hoffmann, A. Junger, M. Krueger, G. Schuermann, H. Wang, K. Dirscherl, H. Dittmer, M. Oertel: DE102016215750A1 – Licht- und temperaturempfindlicherHalbleitersensor, Robert Bosch GmbH, 2018

[14] F. Lukacs, A. Dannenberg, F. Heuck, H. Grutzeck, M. Schwarz, R. Maul, T. Dögei, T. Friedrich, V. Senz: US11060937B2 – Micromechanical pressure sensor, Robert Bosch GmbH, 2021

[13] F. Lukacs, A. Dannenberg, F. Heuck, H. Grutzeck, M. Schwarz, R. Maul, T. Dögei, T. Friedrich, V. Senz: CN110383027A – Micromechanical pressure sensor, Robert Bosch GmbH, 2019

[12] F. Lukacs, A. Dannenberg, F. Heuck, H. Grutzeck, M. Schwarz, R. Maul, T. Dögei, T. Friedrich, V. Senz: WO2018158116A1 – Micromechanical pressure sensor, Robert Bosch GmbH, 2018

[11] F. Lukacs, A. Dannenberg, F. Heuck, H. Grutzeck, M. Schwarz, R. Maul, T. Dögei, T. Friedrich, V. Senz: DE102017203384B3 – MikromechanischerDrucksensor, Robert Bosch GmbH, 2018

[10] M. Schwarz, T. Friedrich, T. Brückner: SE1850080A1 – Sensor device for measuring a fluid concentration, and use of the sensor device, Robert Bosch GmbH, 2018

[9] M. Schwarz, T. Friedrich, T. Brückner: CN107835939A – Sensor device for measuring a fluid concentration, and use of the sensor device, Robert Bosch GmbH, 2018

[8] M. Schwarz, T. Friedrich, T. Brückner: US20180188157B2 – Sensor device for measuring a fluid concentration, and use of the sensor device, Robert Bosch GmbH, 2018

[7] M. Schwarz, T. Friedrich, T. Brückner: WO2017005404A1 – Sensor device for measuring a fluid concentration, and use of the sensor device, Robert Bosch GmbH, 2017

[6] M. Schwarz, T. Friedrich, T. Brückner: DE102015212870A1 – SensorvorrichtungzumMesseneinerFluidkonzentration und Verwendung der Sensorvorrichtung, Robert Bosch GmbH, 2017

[5] M. Hiemer, M. Schwarz: CN102007019A – Method and control unit for activating at least one safety device, Robert Bosch GmbH, 2011

[4] M. Hiemer, M. Schwarz: EP2276650A1 – Method and control unit for activating at least one safety device, Robert Bosch GmbH, 2011

[3] M. Hiemer, M. Schwarz: US20110153164A1 – Method and control unit for activating at least one safety device, Robert Bosch GmbH, 2011

[2] M. Hiemer, M. Schwarz: WO2009127453A1 – Method and control unit for activating at least one safety device, Robert Bosch GmbH, 2009

[1] M. Hiemer, M. Schwarz: DE102008001215A1 – Verfahren und SteuergerätzurAnsteuerung von zumindesteinemSicherheitsmittel, Robert Bosch GmbH, 2008

Send Us A Message

Whether you are curious about the our work or want to collaborate with us, reach out to us. We are listening.